A Guide to Automated Quality Management

For years, quality management in contact centers has been stuck in the past. It's a world of manual spot-checks, where a supervisor listens to a handful of calls and hopes to find something useful. This old way of doing things is slow, riddled with bias, and leaves huge gaps in your understanding of the customer experience.

But what if you could analyze 100% of your customer interactions? Not just a random 1-3%, but every single one. That’s the promise of automated quality management. It’s a shift from guessing to knowing, using technology to get a complete, unbiased picture of performance, compliance, and customer sentiment across the board.

The End of Manual Spot Checks

Think of the traditional quality assurance (QA) process like a security guard trying to watch an entire stadium by peeking through one tiny keyhole. They might spot something, but they're missing the vast majority of the action. This is exactly what happens when QA specialists manually review a tiny sample of calls.

The whole process is fundamentally broken. It’s incredibly labor-intensive, which means feedback for agents is often delayed by days or even weeks long after the conversation is a distant memory. The real danger, though, lies in the massive blind spots. What compliance breaches, churn risks, or broken processes are hiding in the 97% of interactions you never hear?

Why Automation Is No Longer Optional

In today's competitive environment, that margin for error is no longer acceptable. Customers demand better service, regulations are stricter than ever, and operational efficiency is paramount. Companies are waking up to this reality, and the numbers show it. The industrial automation market is on track to hit $226.8 billion in 2025.

It's not just about spending money on new tech; it's about real-world results. Businesses that invest in automation see an average 22% reduction in operating costs. If you want to dig deeper, you can explore more automation statistics that paint a clear picture of this global shift.

"Automated quality management isn't just about replacing manual tasks; it's about elevating quality assurance from a reactive chore to a proactive, strategic function that drives business growth."

So, what’s really pushing this change? A few key things:

Speed and Scale: Automation gives you the power to analyze every single interaction almost instantly. A human team simply can't compete.

Objectivity and Consistency: It takes human bias out of the equation. Every agent is measured against the exact same standards, ensuring fairness and consistency.

Deep, Actionable Insights: When you analyze the entire dataset, you start seeing the big picture. You can spot systemic problems and trends that are completely invisible when you're only looking at small samples.

Let's break down the differences between the old and new ways of thinking about quality.

Manual vs Automated Quality Management At a Glance

The table below gives a quick snapshot of how these two approaches stack up. It really highlights the fundamental gap between relying on manual checks and embracing a fully automated system.

Looking at this comparison, the conclusion is pretty clear. While manual checks once served a purpose, they can no longer provide the speed, precision, or comprehensive insight needed to thrive. Moving to an automated system isn't just a technical upgrade; it's an essential evolution for any modern business. Book A Call

How Automated Quality Management Actually Works

So, what’s really going on under the hood of an automated quality management system? Think of the safety systems in a modern car. It’s packed with sensors - cameras, radar, you name it all feeding data to a central computer. That computer processes everything in a split second to spot a potential crash and can slam on the brakes faster than you could ever hope to react.

Automated quality management applies that same idea to your business, whether it's on a factory floor or in a contact center. It's about moving away from spot-checking and catching mistakes after they've already happened. The goal is to build quality into the process from the start, making it proactive instead of reactive.

The Core Components of Automation

At its heart, this technology is built on three pillars that work in a constant, looping cycle. Each piece is essential for keeping standards high without a human needing to watch over every little detail.

Real-Time Monitoring: This is the system's eyes and ears. On a production line, it could be high-res cameras or temperature sensors. In a contact center, it’s software that analyzes 100% of customer interactions as they happen. This constant flow of data is the raw material for everything else.

Intelligent Analysis: All that data gets funneled into an analysis engine. Using a mix of predefined rules and, more and more, artificial intelligence, this engine hunts for anything that deviates from the ideal standard. It’s not just looking for massive failures; it’s looking for the tiny variations that might hint at a bigger problem down the road. This is where methods like statistical process control (SPC) shine, helping to keep processes stable.

Automated Correction: This is where the system closes the loop. When it spots a problem, it doesn’t just raise a flag, it triggers an immediate, automatic response to fix it.

Creating a Closed-Loop Feedback System

When you put these three components together, you get what’s called a closed-loop feedback system. It’s a fancy term for a simple concept you already know: a thermostat. Your thermostat constantly checks the room temperature (monitoring), compares it to your desired setting (analysis), and kicks the heat on or off to match it (correction).

An automated quality system does the exact same thing, just on a much bigger and more complex scale.

"A closed-loop system is a powerful framework because it's self-regulating. It doesn't just flag problems for a human to fix later; it makes adjustments in real time to keep the entire process stable and predictable, ensuring consistent quality output."

For instance, if a machine tool starts drifting a few microns off-spec, the system can instantly recalibrate it. Or if a call center agent keeps forgetting a critical compliance phrase, the system can flag the interaction for immediate review and assign a quick micro-coaching module. This ability to self-correct in the moment is what makes automated quality management so valuable, it turns quality from a periodic audit into a living, intelligent part of your operations. Book A Call

The Real Business Impact of Quality Automation

It’s easy to get lost in technical diagrams and software features, but what does switching to automated quality management actually do for a business? The truth is, its impact reaches far beyond the factory floor or the contact center, creating real strategic advantages that show up on the bottom line. It’s all about shifting quality from a necessary expense to a powerful engine for growth.

Think about a company that makes thousands of life-saving medical implants every day. A single, tiny production mistake could snowball into a multi-million dollar recall. The damage to their reputation would be massive, and worse, it could put patients at risk. With an automated system in place, they can monitor every single component as it’s made, catching microscopic flaws before they ever become critical defects.

That kind of proactive approach doesn't just prevent disaster; it builds an undeniable business case for automation. This is precisely why the global market for automated industrial quality control is set to explode, projected to more than double from $21.40 billion in 2024 to over$50.51 billion by 2035.

The Strategic Pillars of Quality Automation

The advantages of automated quality management really boil down to three core business pillars. Each one directly strengthens a company's financial health, operational stability, and long-term standing in the market. We're not talking about small tweaks here, we're talking about a fundamental upgrade to how a business runs.

"Automated quality management protects revenue by ensuring unwavering product consistency, slashes costs by eliminating waste and rework, and builds a stronger brand reputation one perfect product at a time."

This powerful trio creates a serious competitive edge. Companies that embrace automation can simply move faster, operate leaner, and deliver a level of quality that manual checks can't hope to match. For many, exploring AI automation for small business offers a clear path to getting these results without a massive initial investment.

Here’s how these pillars translate into tangible business wins:

Significant Cost Reduction: When you catch defects early, you dramatically cut down on expensive rework, scrapped materials, and wasted labor. Automation prevents faulty products from ever reaching customers, saving you from the crippling costs of returns and warranty claims.

Revenue and Brand Protection: Consistent quality is the bedrock of customer trust and loyalty. By ensuring every product meets the same high standard, automation acts as a guard for your brand's reputation and protects future sales from the damage of a quality failure.

Enhanced Operational Efficiency: With automated systems handling the repetitive monitoring, your skilled people are freed up to focus on what they do best, innovation and improving processes. This shift boosts productivity and smooths out the entire production cycle.

How AI and Machine Learning Elevate Quality Control

Automated quality management systems are fantastic at following a set of rules, but when you add artificial intelligence (AI)and machine learning (ML) into the mix, they learn to think. This is the turning point where quality control stops being reactive and becomes truly predictive. We're moving beyond just catching defects after they happen to anticipating them before they ever have a chance to occur.

Think of it as the difference between a smoke detector and a weather forecast for your production line. A basic system tells you there's a problem right now, the smoke detector is blaring. An AI-powered system, on the other hand, analyzes all the subtle data points to warn you that a storm is brewing days in advance. That heads-up gives you the time to prepare, make adjustments, and avoid disaster altogether.

From Detection to Prediction

Traditional automation is a workhorse. It's fast, consistent, and tireless. But it can’t see the forest for the trees; it lacks the intuition to interpret subtle patterns. AI and machine learning algorithms are built for this. They can chew through massive amounts of data from sensors, cameras, and production logs to spot correlations a human would never notice.

This lets them move beyond simple pass/fail checks to answer much deeper questions:

What tiny vibrations in a machine are a tell-tale sign of a future breakdown?

Which microscopic variations in raw materials lead to a higher defect rate down the line?

What patterns in a customer's tone of voice signal they're about to churn?

By identifying these leading indicators, automated quality management transforms into a proactive powerhouse. It can flag a machine that’s about to fail, preventing a costly shutdown, or alert you when a product line is slowly drifting out of spec. It’s a fundamental shift from just detecting problems to actively predicting them.

This isn’t just a nice-to-have; it's becoming essential. Take the medical device industry, which has seen a staggering 115% increase in product recalls since 2018. Those recalls cost companies an estimated $5 billion a year. This is exactly the kind of high-stakes problem where AI-driven prediction can make a world of difference. Book A Call

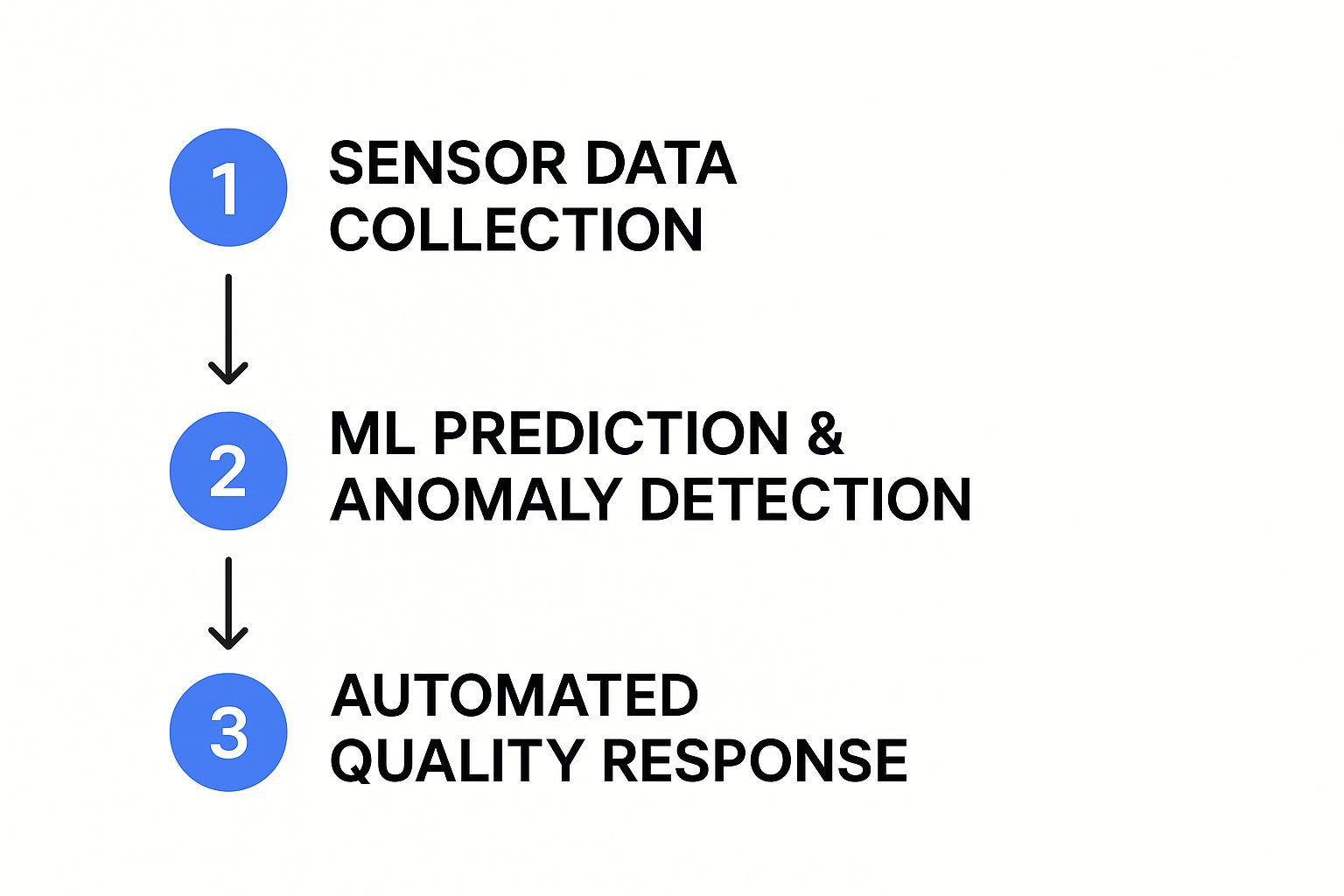

This infographic lays out the simple, yet powerful, workflow AI brings to the table.

As you can see, it creates a feedback loop where data feeds predictions, and those predictions trigger smart, automated actions to keep quality standards high.

Practical Applications of Intelligent Automation

AI-powered systems aren't some far-off concept; they're delivering real results today. For example, AI-driven computer vision can spot microscopic cracks or color variations on a fast-moving assembly line with an accuracy and speed no human inspector could ever hope to match.

"The real magic is that machine learning algorithms learn from past data. They constantly refine their definition of "perfect," getting smarter and more accurate with every product they analyze. This self-improvement is what separates a good system from an intelligent one."

And this kind of technology is no longer just for massive corporations. Many of the core ideas behind industrial automation are available in different packages, and it's worth exploring some of the best AI tools for small business to see how these concepts can be applied on a different scale. At the end of the day, AI and ML turn automated quality management from a rigid rule-follower into an adaptive, intelligent partner that actively prevents problems and ensures you’re delivering the best product possible.

Your Roadmap to Implementing an Automated QMS

Making the switch to an automated quality management system isn't just about installing new software. It's a strategic move, much like building a custom home. You wouldn't start pouring a foundation without a detailed blueprint, right? The same principle applies here. A successful implementation hinges on careful planning that brings your technology, processes, and people into perfect alignment.

Jumping in without a solid plan is a fast track to problems. If you have vague goals, your team isn't on board, and you haven't really audited your current workflows, the project can easily go off the rails. You end up with wasted money and a system no one wants to use.

This roadmap breaks the journey down into manageable steps, making sure you build a solution that truly delivers.

Phase 1: Assess Your Current State

Before you can figure out where you’re going, you need a brutally honest map of where you are right now. The first step is to take a hard look at your existing quality management processes. The goal is to pinpoint the exact bottlenecks, inefficiencies, and daily frustrations that are holding you back.

This isn’t just an exercise in looking at flowcharts. You have to get out there and talk to the people on the front lines—the operators, inspectors, and managers who live and breathe these workflows every single day. Their insights are gold when it comes to understanding where the system is actually breaking down.

Here are a few key questions to get you started:

Where are the biggest delays in our quality feedback loop?

Which tasks are most susceptible to human error or inconsistency?

What are the most significant compliance risks we're currently facing?

Phase 2: Define Clear Objectives

Once you have a clear picture of your challenges, it's time to define what "success" actually looks like. Vague goals like “improve quality” just won’t cut it. You need sharp, specific, and measurable objectives that give your automated quality management project a clear destination.

These objectives should connect directly to real business outcomes. For instance, instead of a fuzzy goal, aim for something concrete like, "Reduce product defect rates by15%within six months," or "Cut compliance-related errors by 25% by the end of the year." This approach makes sure your investment is tied to tangible improvements you can see on the balance sheet.

"A well-defined set of Key Performance Indicators (KPIs) is your compass for this journey. It keeps the team focused, helps justify the investment, and gives you a clear way to measure your return on investment (ROI)."

Phase 3: Choose the Right Technology and Launch a Pilot

Now that you know your goals, you can start picking the right tools for the job. This means selecting a technology stack, from sensors and cameras to the central software platform that fits your specific needs. It’s critical to find a solution that not only meets your technical requirements but also plays nicely with your existing systems.

Instead of trying to boil the ocean with a full-scale rollout, start small with a focused pilot project. Pick a single production line or a specific process to test the new system in a controlled environment.

A pilot project is a smart move because it allows you to:

Prove the concept and see how the tech performs in a real-world setting.

Calculate a tangible ROI using actual performance data.

Find and fix unexpected problems on a small scale before they affect the whole company.

This phased approach builds confidence and creates internal champions who will advocate for the project. For businesses mapping out this journey, developing a robust framework is key. You can find guidance on this by exploring our insights on strategic AI planning.

Phase 4: Scale and Manage the Change

With a successful pilot in the bag, you can move forward with scaling the solution across the rest of the organization. This final phase is just as much about people as it is about technology. Getting the change management right is absolutely essential for smooth adoption and long-term success.

This means providing thorough training, clearly communicating the benefits of the new system, and getting employees involved in the transition. When you can show your team how automated quality management actually empowers them to do their jobs better, you can turn potential resistance into enthusiastic support.

Implementation Roadmap for Automated Quality Management

To help visualize the journey, here’s a phased guide outlining the key steps, objectives, and potential challenges you might encounter when deploying an automated QMS.

Following a structured roadmap like this one helps demystify the process and keeps your team aligned from start to finish, ensuring your transition to automated quality management is a resounding success. Book A Call

Got Questions About Automated Quality Management?

Making the switch to an automated quality management system is a big move. It’s completely normal to have questions when you’re thinking about shifting from the manual processes you know to a more data-centric, automated approach. It can feel like a huge leap.

To help clear things up, we've put together answers to some of the most common questions we hear from leaders who are considering this change.

Will Automation Make Our Human Inspectors Obsolete?

This is easily one of the most common and most important questions we get. The short answer is no. Automated quality management is designed to elevate your team, not replace them. Think of it as giving your quality assurance pros a set of superpowers.

Automation is brilliant at handling the repetitive, high-volume work with flawless consistency, like analyzing 100% of customer interactions or sifting through thousands of data points every second. This gets your skilled inspectors out of the weeds of tedious manual reviews.

"Instead of spot-checking for basic mistakes all day, your team gets to focus on work that truly requires their expertise. They can dig into complex trends, figure out the root causes of recurring problems, and design smarter ways to improve your entire process."

In other words, automation takes care of the "what," freeing up your people to focus on the "why" and the "how do we make this even better?"

What's a Realistic ROI for an Automated QMS?

While the exact return on investment (ROI) will depend on your industry and how you implement the system, most businesses see a return in a few key areas. The most immediate win is almost always a big drop in operational costs, since automating reviews cuts down dramatically on the labor hours needed for manual QA.

But the financial upside goes way beyond just direct cost savings:

Less Waste and Rework: When you catch defects early, you minimize scrapped materials and avoid expensive rework. For some companies, this alone can add up to millions in savings.

Lower Compliance Costs: Automated monitoring keeps you on the right side of regulations, which significantly lowers your risk of facing hefty fines and penalties.

Better Customer Retention: Delivering consistent quality makes for happier, more loyal customers, which is the best way to protect your long-term revenue.

Many organizations find that the savings from these areas create a strong ROI within the first 12-18 months.

How Can We Get Started If We Have a Limited Budget?

The thought of rolling out a major new technology platform can feel intimidating, especially when budgets are tight. The good news is, you don’t have to do a massive, all-at-once overhaul to start seeing the benefits of automated quality management.

A phased rollout is usually the smartest and most budget-friendly way to go. Start small by picking the single biggest headache in your current quality process. Is there a specific production line that always has a high defect rate? Or a tricky compliance rule that’s a nightmare to monitor by hand?

Zero in on that one target and launch a small pilot project to solve that specific problem. A successful pilot accomplishes two critical things:

It gives you a clear, measurable ROI that you can use to build a strong business case for more investment.

It lets your team get comfortable with the new technology in a controlled, low-risk setting.

This "start small, prove the value" approach allows you to demonstrate wins quickly and build momentum for a wider rollout, all without needing a massive upfront investment.

Ready to turn your quality assurance from a manual chore into a strategic engine for growth? Engage AI specializes in building intelligent automation solutions that deliver real, measurable results. Find out how we can help you get 100% visibility and unlock proactive insights at https://engagemyai.com.